Through our years of expertise in pneumatics and vacuum technology, we have specialized in the development and implementation of custom-built control cabinets tailored precisely to our customers' needs. Each cabinet is crafted as a unique solution that not only meets specific technical requirements but also integrates seamlessly into the spatial and operational conditions of its installation site. Our solutions range from compact control units for mobile applications to complex cabinet systems for large-scale industrial plants, all while guaranteeing the highest quality standards and future-proof design.

Our control cabinets are custom-built for you:

Precise dimensions tailored to your installation site: Using modern CAD systems and 3D simulations, we ensure every component is positioned with millimeter accuracy — even in tight spaces or unconventional mounting scenarios.

Flexible material selection based on environmental conditions: Whether stainless steel housings for corrosion-prone environments, dirt-repellent surfaces like plastic for the food industry, or sound-dampening elements for noise-sensitive areas — we select materials that meet your demands.

Custom equipment and configuration: From basic setups with standard components to high-end control elements with IoT capabilities, we offer modular, expandable solutions that adapt to your processes — not the other way around.

Optimal integration into existing systems: By using cross-manufacturer interfaces and adapting to established protocols like Profibus, Ethernet/IP, or OPC UA, we ensure smooth communication with your plant control systems.

Individually for you

Control cabinet construction plays a central role in pneumatics.

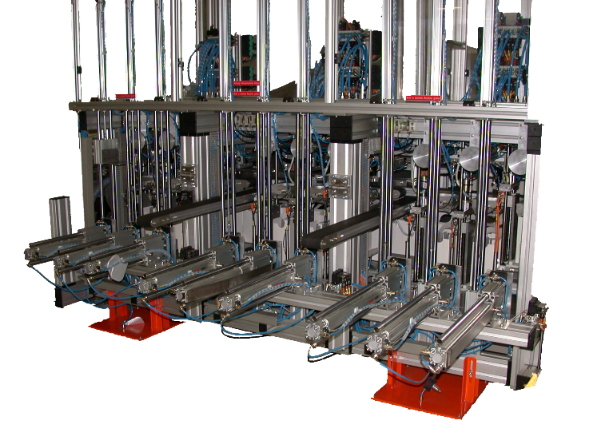

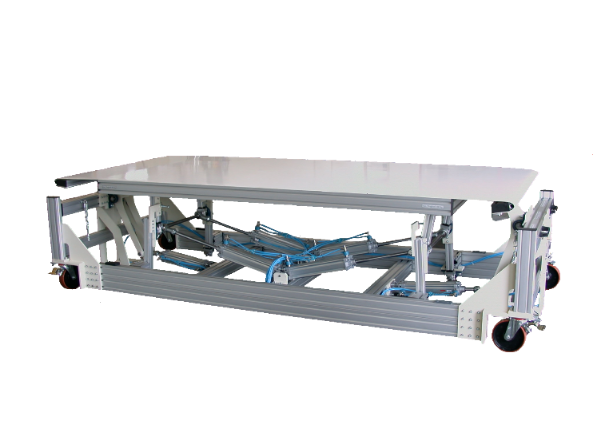

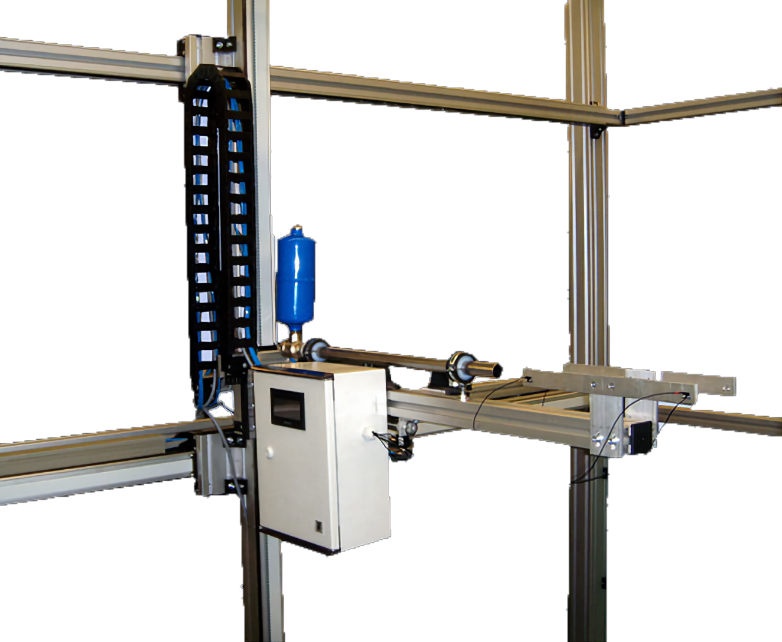

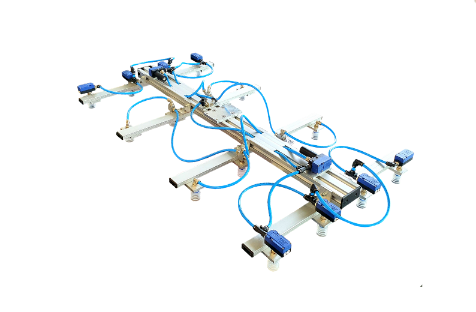

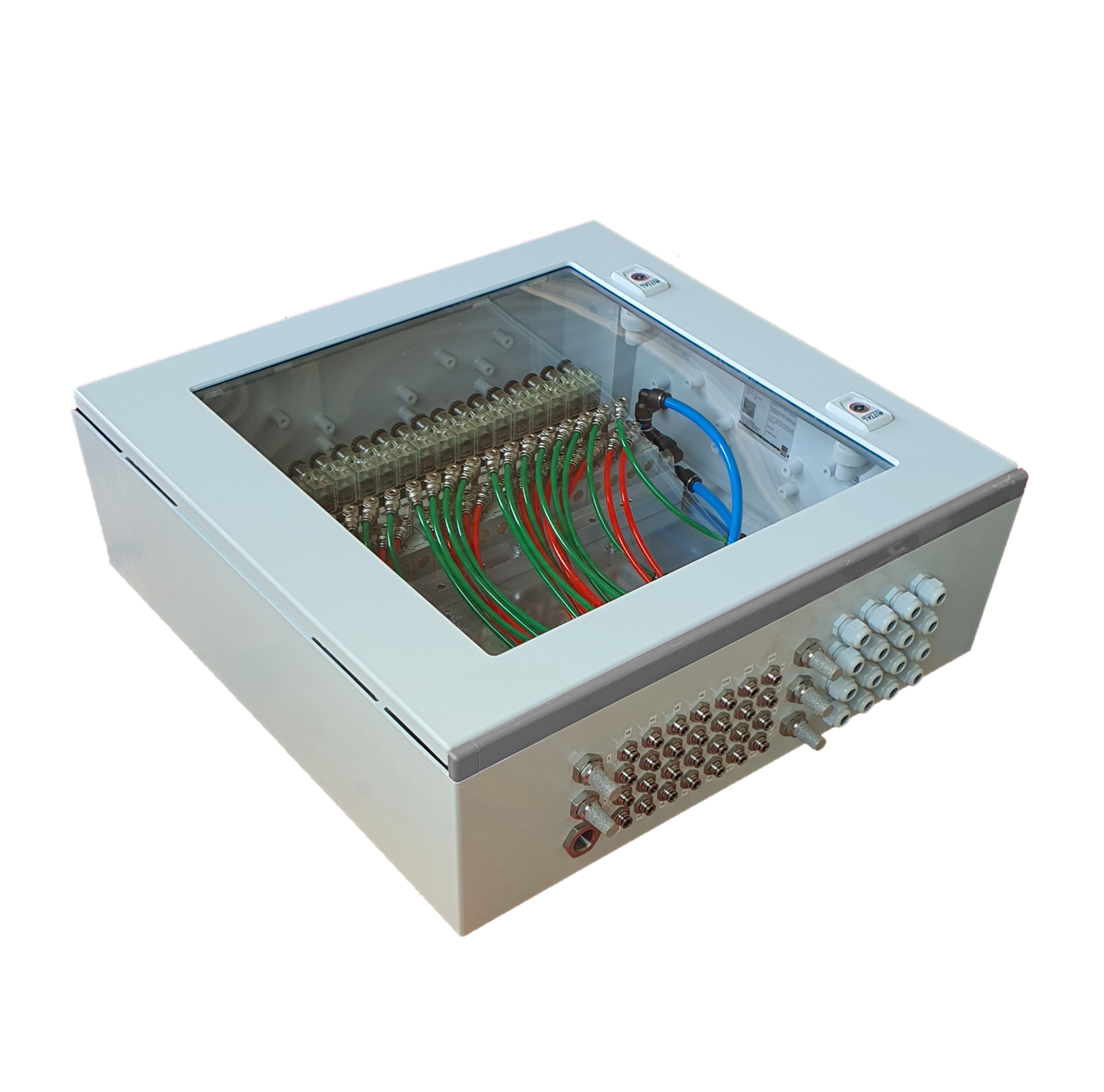

While electrical systems primarily process electrical signals, pneumatics involves the control of compressed air. This air is used to move machines, valves, or cylinders. To ensure that everything functions reliably, the individual components must be housed, connected, and controlled in a switch cabinet. The control cabinet is the heart of the entire system. It ensures that all pneumatic processes run precisely and can be controlled safely. A pneumatic control cabinet usually contains various elements that are coordinated with each other. These include compressed air preparation, valve islands, control units, hoses, couplings, and electrical components. The combination of mechanical, electrical, and pneumatic components makes switch cabinet construction particularly challenging.

All components must be installed in such a way that they are easily accessible, the cables are neatly arranged, and safety is guaranteed at all times. Neat wiring and clear labeling are therefore essential. Clarity plays a major role in the design of a pneumatic switch cabinet. Each connection must be clearly traceable so that maintenance or repair work can be carried out quickly later on. The air supply must also be carefully planned. The pressure must be evenly distributed, and leaks must be avoided at all costs. Even small leaks can cause cylinders to malfunction or valves to respond too slowly. For this reason, all lines and connections are thoroughly checked before the control cabinet is put into operation.

Another important point is the connection between the pneumatic and electrical controls. In modern systems, pneumatic valves are often actuated by electrical signals. This means that the control cabinet not only distributes the air, but also controls the electrical operation of the components. For this purpose, PLC systems (programmable logic controllers) or other control devices are installed to regulate the machine's movements. This allows complex pneumatic systems to be controlled precisely and automatically. Safety also plays a major role in control cabinet construction. Compressed air is a powerful source of energy, and errors in the control system can lead to dangerous situations. For this reason, safety valves, pressure monitoring, and emergency stop switches are integrated. These systems ensure that pressure is quickly reduced or the system automatically stops in the event of a fault.

Moreover, all components must comply with applicable standards and regulations to ensure that operation remains safe at all times. In addition to functionality, ease of maintenance is also important. A well-designed pneumatic control cabinet allows defective components to be replaced quickly without shutting down the entire system. A clear structure, good labeling, and clean installation make the work much easier. The design of the housing also plays a role: it protects the sensitive components from dust, moisture, and external influences. Especially in industrial environments, this is a decisive factor for the service life of the system. Overall, control cabinet construction in pneumatics is a combination of precision, technology, and experience. Every system has its own requirements, which is why each control cabinet is planned and built individually.

This is the only way to ensure that the pneumatic processes run efficiently, safely, and reliably. A well-designed pneumatic control cabinet is therefore not just a technical component, but an essential part of modern automation technology.

Deutsch

Deutsch