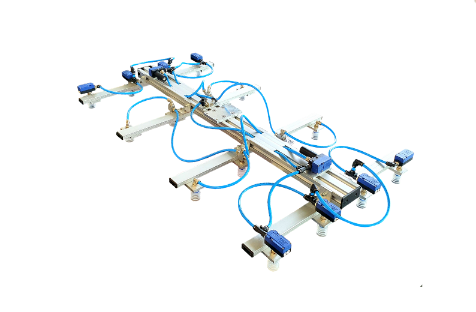

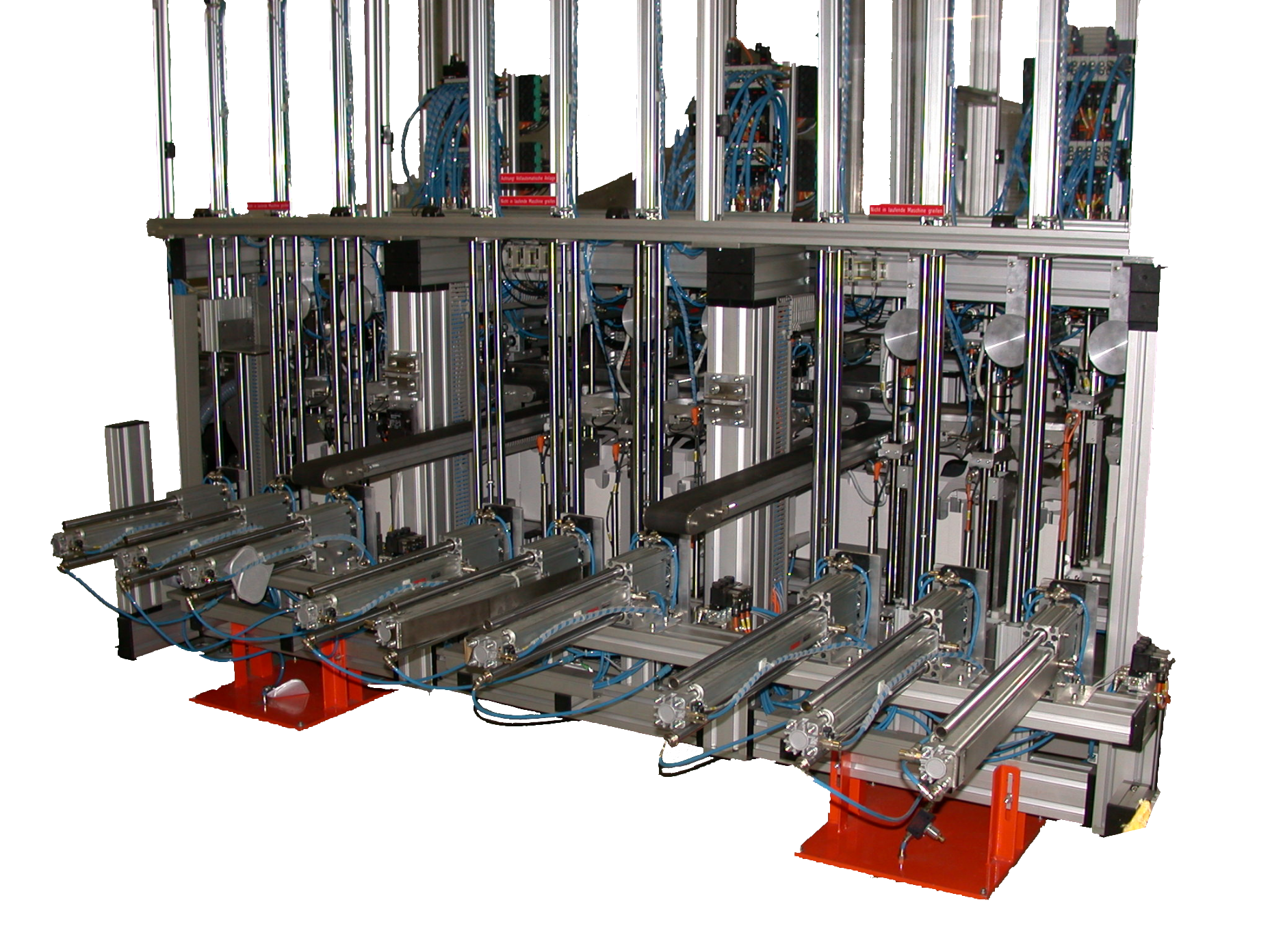

This state-of-the-art sorting system, equipped with 18 cylinders, 24 valves, and 72 vacuum suction cups, can recognize, capture, and precisely sort various lid types for the food industry at an impressive processing speed of 300 cycles per minute. Thanks to its powerful drive technology and intelligent control electronics, the system operates with high energy efficiency and minimal maintenance requirements.

Furthermore, special high-resolution optical sensors, combined with advanced image processing software, enable reliable differentiation between 30 different print patterns, ensuring rapid detection and sorting into the appropriate containers. The system’s integrated learning function also allows for continuous improvement in recognition accuracy.

Additionally, the machine features an automatic rejection function for sample pieces and damaged lids, using innovative defect detection to reliably identify even minor material flaws or color deviations. Another highlight is the unrestricted ability to partially replace punching tools during operation, significantly boosting productivity. Optionally, the system can be expanded with a fully automated feeding and packaging unit to ensure seamless end-to-end production.

Specifications & Details

Deutsch

Deutsch