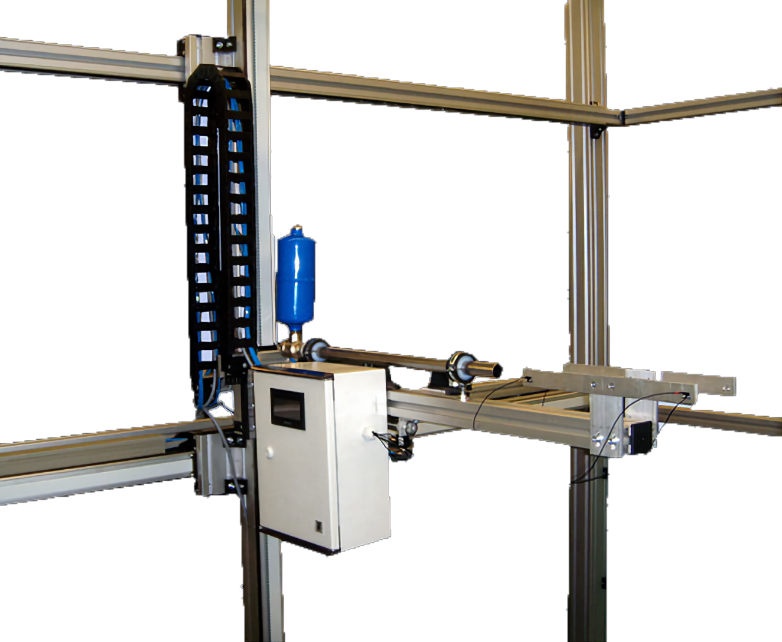

The hail testing facility serves as a highly specialized testing system designed to evaluate the durability of photovoltaic and solar modules under extreme weather conditions. At the core of this system lies an advanced hail projection mechanism that propels artificially manufactured hailstones with precisely adjustable pressure ranging between 1.5 and 3 bar. This technology enables realistic simulations of hailstorms, where the synthetic ice pellets achieve velocities of up to 126 km/h, equivalent to the forces encountered during severe weather events. Depending on testing requirements, the impact intensity can be flexibly adjusted, allowing the hailstones' velocity to be gradually reduced to 65 km/h to replicate different intensity levels of hailstorms.

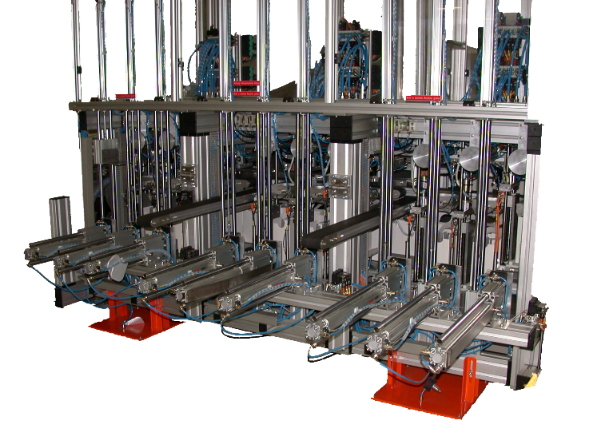

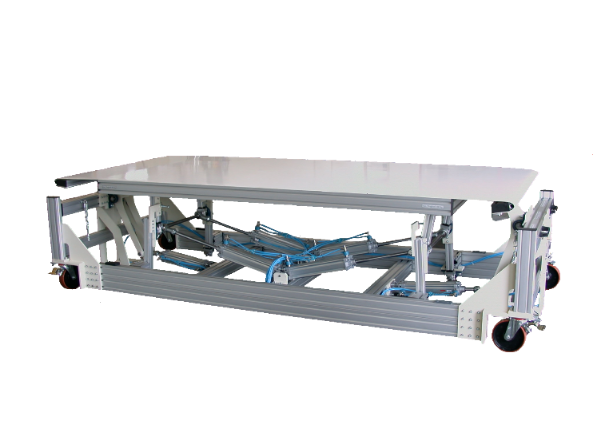

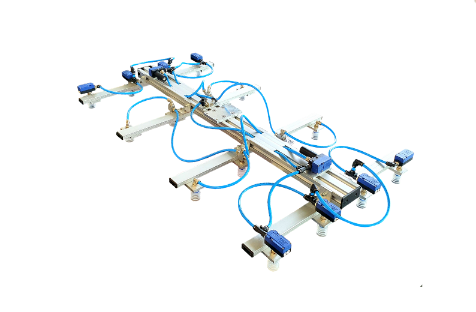

During the initial development phase, the hail projection system was only available as a semi-automatic setup, requiring manual positioning of the test modules. This manual alignment process not only demanded additional time but also introduced potential inaccuracies in test execution. To overcome these challenges, the system has been continuously refined and now incorporates modern electrical positioning systems. This upgrade enables fully automated, precise module alignment, significantly simplifying operation while enhancing the reproducibility of test results. The integration of these electrical control systems allows not only for more efficient operation but also enables the programming of complex test sequences, facilitating comprehensive quality assessments under variable conditions.

By simulating diverse impact scenarios, engineers can now analyze material responses at different angles and intensities, providing critical data for improving protective coatings and structural designs. The system plays a vital role in enhancing photovoltaic reliability, particularly for installations in regions prone to frequent hailstorms, ultimately contributing to more resilient renewable energy infrastructure. Through its sophisticated testing protocols, the facility helps manufacturers meet international certification standards while reducing warranty claims and maintenance costs associated with weather-related damage. This technological innovation represents a crucial step forward in sustainable energy development, ensuring solar panels maintain optimal performance throughout their operational lifespan.

Specifications & Details

Deutsch

Deutsch