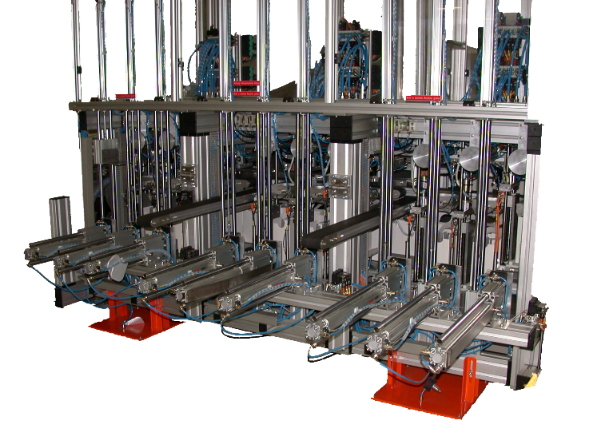

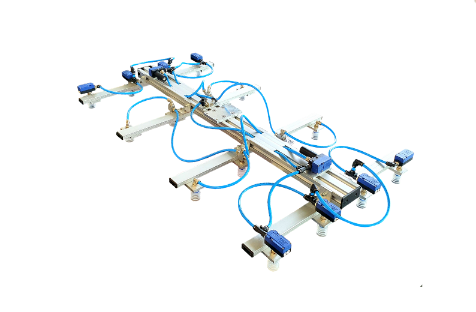

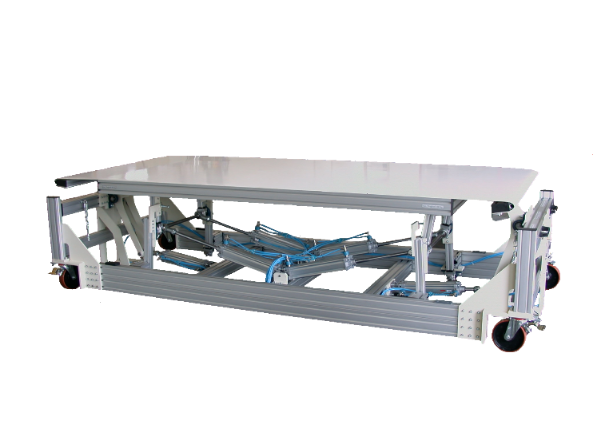

This highly specialized machine, primarily used in the abrasive industry, is designed for the precise handling and efficient transportation of abrasive belts of varying sizes and material compositions. By utilizing pneumatically driven cylinders operated with compressed air, the abrasive belts can be shaped into a slightly curved ideal form, ensuring stability during transport while optimizing alignment for subsequent processing stages. The pneumatic control system allows for delicate adjustments to the curvature, enabling exact adaptation to the specific requirements of each production process. The folding table’s maximum load capacity of up to 600 kilograms ensures the safe and uninterrupted movement of even heavy or bulky abrasive belt rolls.

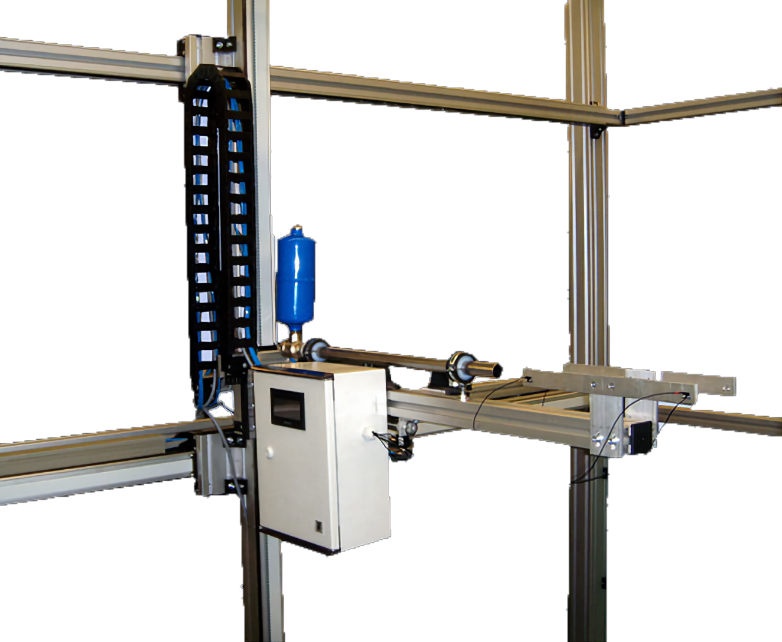

Furthermore, the pneumatic folding table is engineered for seamless integration into existing production lines. Its robust construction and use of durable materials such as galvanized steel or aluminum-reinforced components ensure operational reliability and minimal downtime. The machine is controlled via an intuitive interface, allowing operators to quickly adjust parameters for curvature, transport speed, and positioning. Advanced sensors can also be integrated to monitor belt positioning in real time, enabling automatic corrections if deviations from the target state are detected.

The application of the pneumatic folding table extends beyond the abrasive industry. Its adaptability makes it suitable for related sectors such as paper processing, textiles, or film manufacturing. The modular design allows for custom upgrades to meet specific needs, including enhanced precision, higher speeds, or additional safety features.

Specifications & Details

Deutsch

Deutsch