Our favorite

Pressure load testing systeme

The main objective of this device is to test the load capacity of photovoltaic and solar modules with regard to their stability under bending forces, in which compressive forces of up to 36000 Newtons and tensile forces of up to 17400 Newtons can be achieved. This system is intended to simulate realistic, dynamic wind conditions, whereby the compressive forces alone also make it possible to simulate a static situation, such as the load on snow masses.

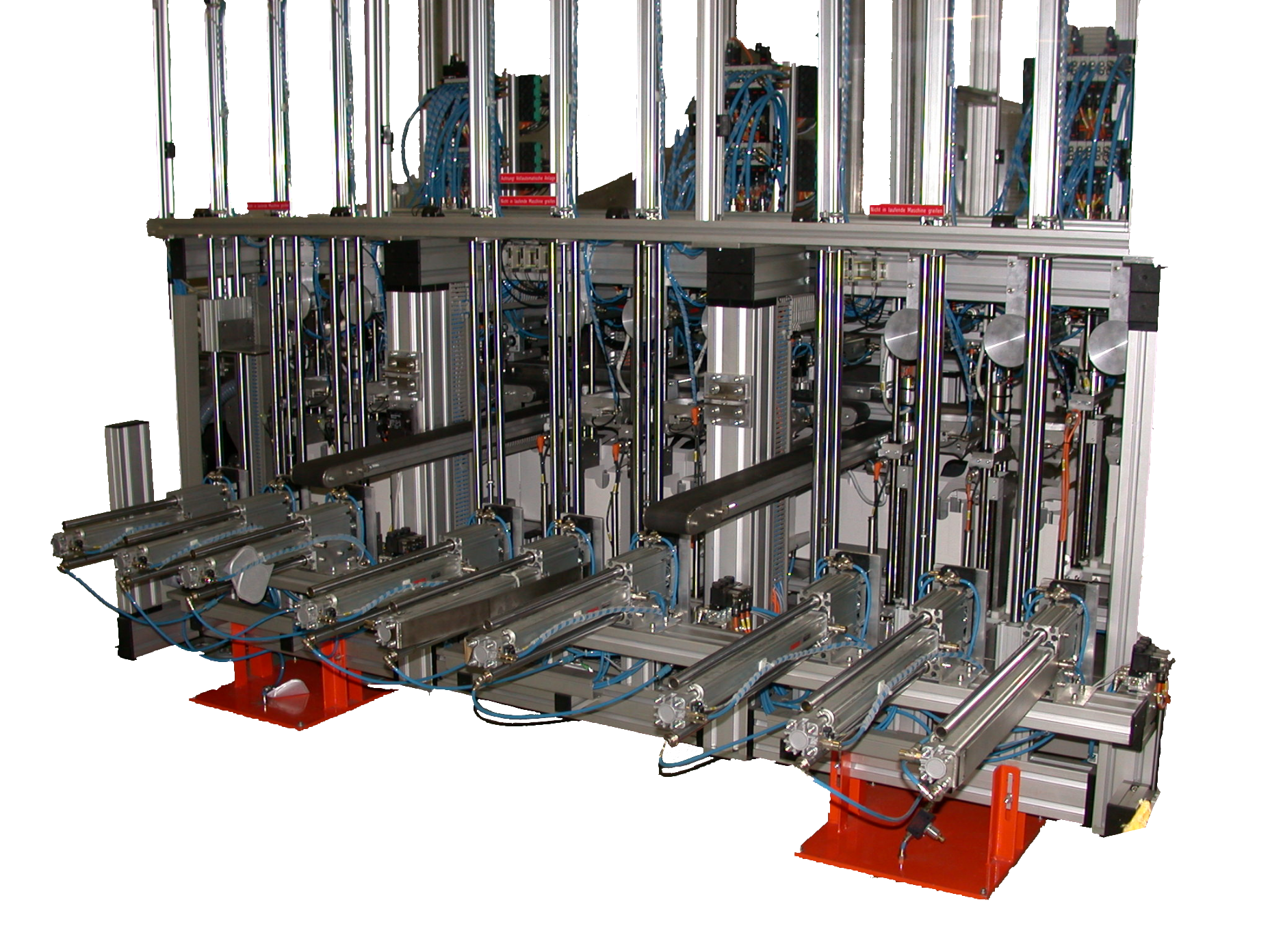

Sorting machine

This sorting system, which was equipped with 18 cylinders, 24 valves and 72 vacuum cups, can detect and sort a wide variety of lid types for the food industry with a processing speed of 300 cycles per minute. In addition, special optical sensors make it possible to distinguish between 30 different print images so that they can be captured and sorted into containers in the shortest possible time. In addition, a separate function for sorting out samples and damaged lids has been installed, as well as the unrestricted possibility of partially changing the punching tools during operation.

Hail testing system

With the help of this hail device, synthetically produced hailstones can be fired at a pressure of 1.5 to 3 bar for load testing on photovoltaic and solar modules. These hailstones reach a speed of up to 126 km/h, whereby the shot power can be variably reduced to up to 65 km/h depending on the application. For the time being, this hailshot system was only implemented in a semi-automatic version, so that the positioning still had to be done by hand. In the meantime, positioning is also controlled by electrical systems to ensure easier and less complicated operation.

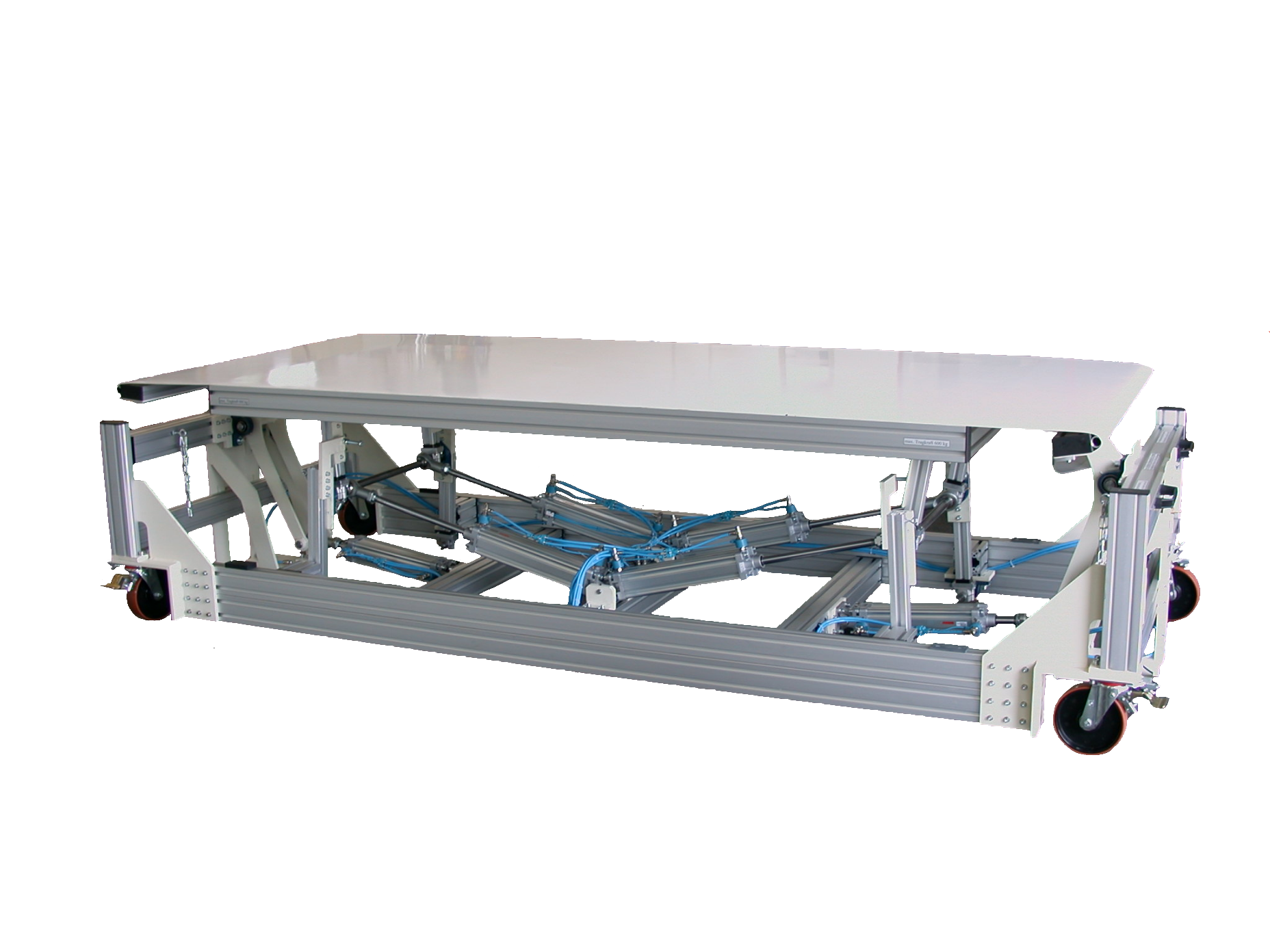

Pneumatic folding table

This machine, which is mainly used in the abrasives industry, is used for handling and transporting abrasive belts. With the help of the pneumatic cylinders, the belts can be brought into a slightly bent ideal shape in which they can be optimally transported.

Maximum load capacity: 600kg

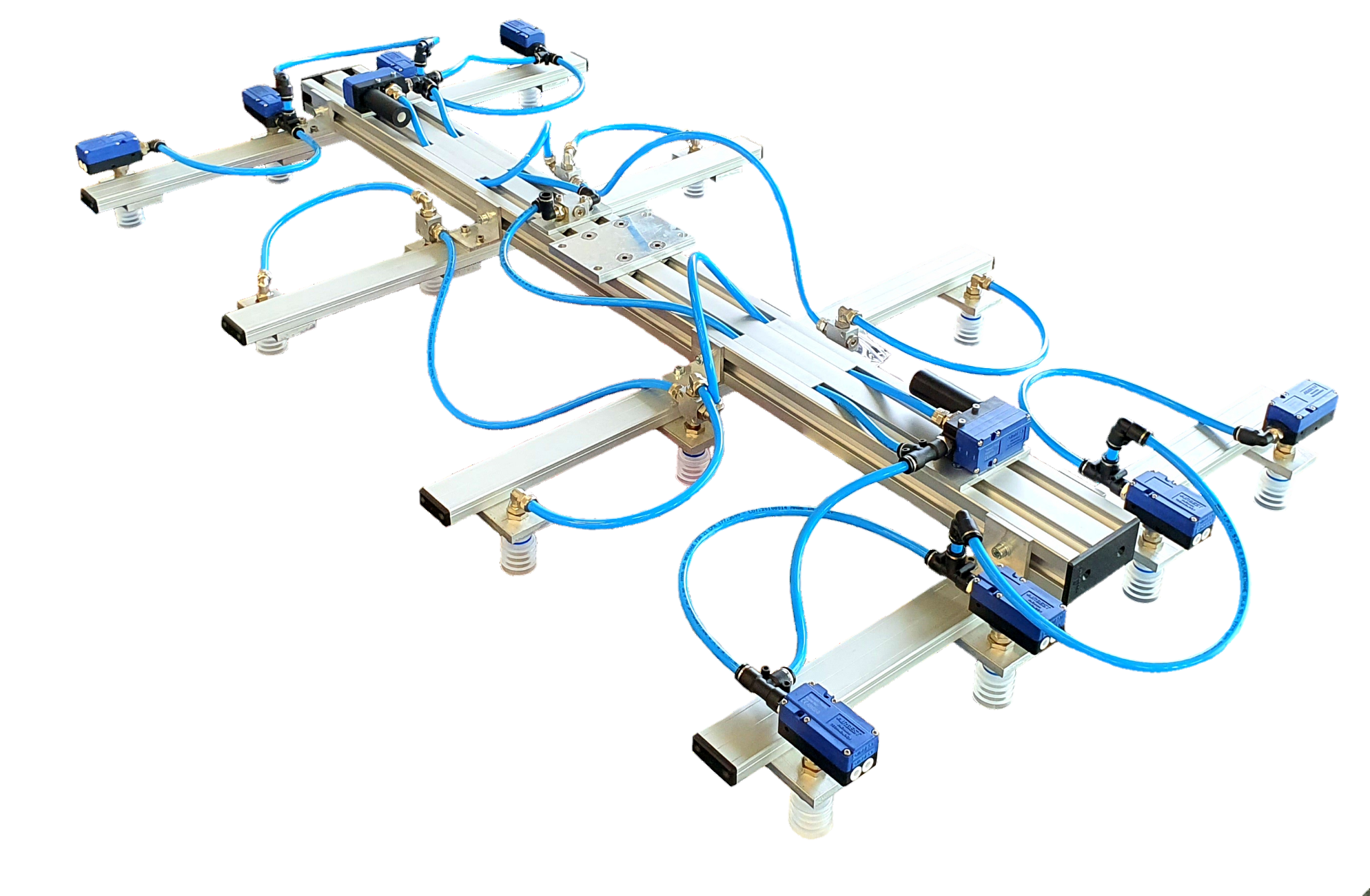

Vacuum Lifting Shuttle

This shuttle unit, equipped with 16 vacuum cups, is used for the onward transport of specially made plastic sheets in insulation technology, which requires extremely precise adjustment of the cups due to its distinctive shapes. In other sizes and designs, these vacuum shuttle units can be used for a wide variety of purposes and in various industries, from the food industry to packaging technology

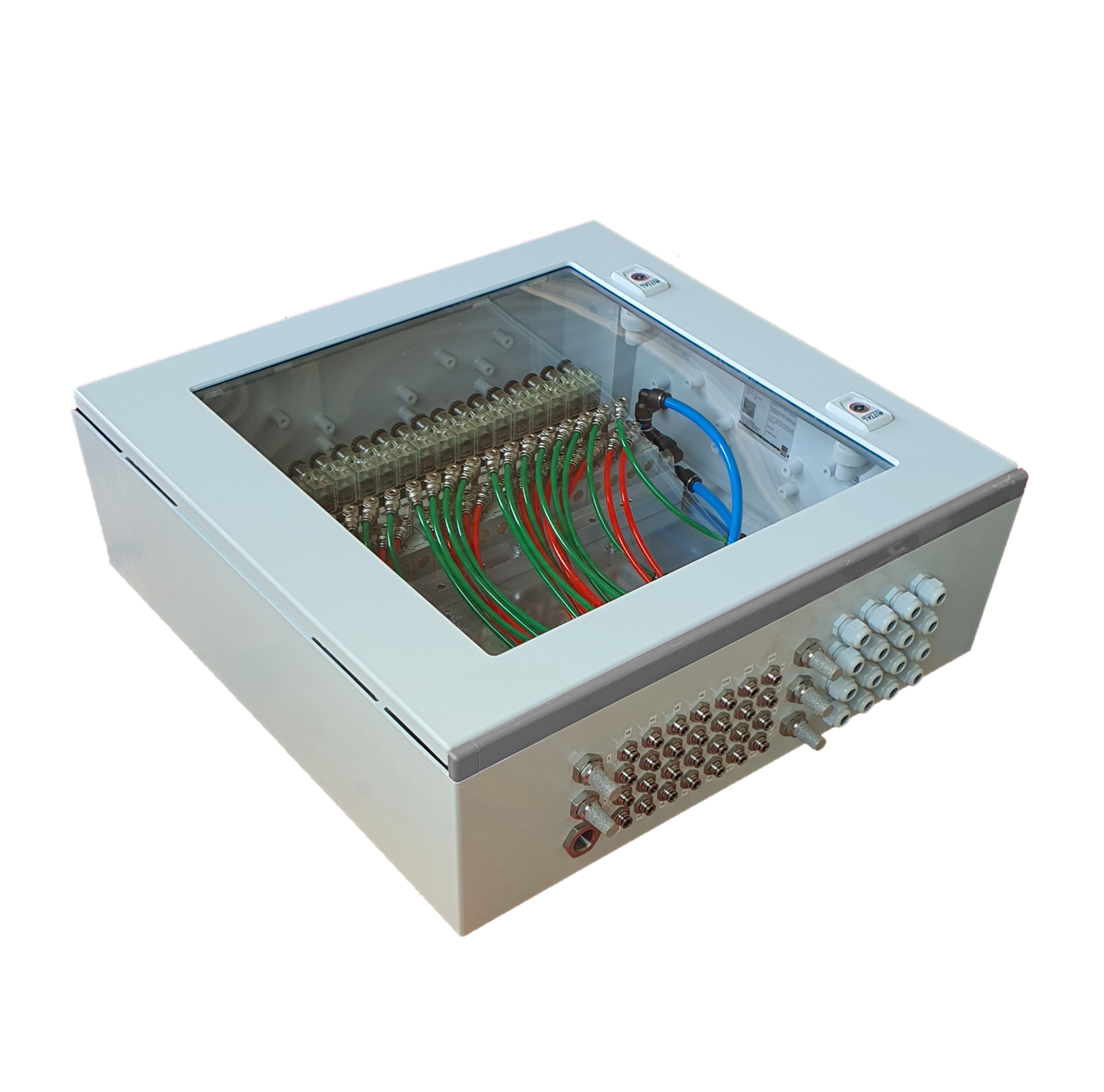

Individual cabinet construction

Thanks to our many years of experience in the field of pneumatic and vacuum technology, we also focus on the individual implementation of customized control cabinets for special customer requirements and applications.

Our cabinets are customized especially for you:

- Precise dimensions to suit your location

- Flexible choice of materials depending on environmental conditions

- Individual equipment and configuration

- Optimum integration into your existing systems

Our experienced team is at your side:

- Detailed analysis of your requirements

- Expert recommendations for the optimum solution

- Detailed planning and design

Deutsch

Deutsch